What Is a Shot Blasting Machine?

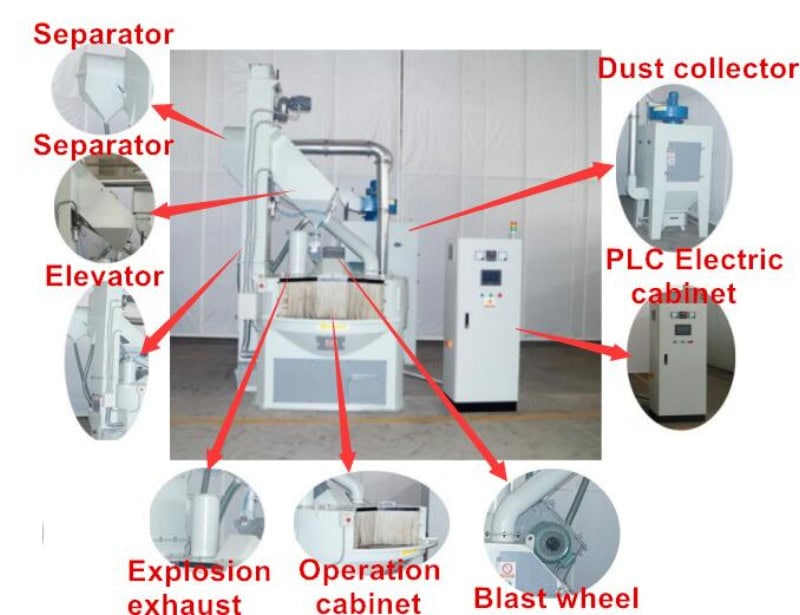

The shot blasting machine functions through blasting metal surfaces with high-speed steel shots or abrasive materials to achieve cleaning and strengthening, or polishing operations. The manufacturing process heavily depends on this equipment because surface quality represents a critical factor.

A reliable blast cleaning system provides consistent results, together with reduced manual labor and improved surface adhesion when treating steel pipes, cleaning weld seams, and preparing parts for coating.

What Affects the Price of a Shot Blasting Machine?

1. A roller conveyor shot blasting machine designed for cleaning large steel plates operates at different price points than portable shot blasting machines intended for maintenance work.

2. The cost of fully automatic shot blasting machines increases with the addition of PLC control and touch screens, as well as blast wheel regulation systems, which also reduce future labor expenses.

3. The price of equipment increases with machine size and throughput capacity, but these larger machines enhance production rates.

4. The price of dust collection and recovery systems increases with advanced models that protect workers and recover abrasive materials. Although the initial cost may be higher, the system will pay itself back in the long term.

Do you require a chamber of unique dimensions or a custom-designed media recovery system? The price of customized machines reflects their value, yet they remain an essential investment. Their cost will be determined by the level of investment made.

Different Types of Shot Blasting Machines and Their Value

The selection of appropriate shot blasting equipment heavily depends on your production needs. The following list presents various machine types along with their most valuable applications.

🔹 Through-type Shot Blasting Machine

Features and scope of application:

This series belongs to the roller table type shot blasting cleaning machine, mainly used in industries such as construction and bridges, for stress relief and surface rust removal of large-sized steel structural components such as l-beams and H-beams.

🔹Tumble Belt Type Shot Blasting Machine

Characteristic:

1. Surface cleaning, rust removal, and shot blasting strengthening processes for various small and medium-sized castings, forgings, and machined parts.

2. It can be used alone or in combination with multiple machines, forming a production cleaning assembly line with continuous conveyors and other supporting equipment.

3. Advanced design, reasonable structure, low energy consumption, and high efficiency.

Scope of application:

Small and medium-sized mold castings, forgings, stamping parts, non-ferrous metal castings, gears, and springs.

🔹Automatic Loading and Unloading Track-Type Shot Blasting Cleaning Machine

Characteristic:

1. Adopting an automatic loading and unloading system to achieve an automated workflow, reduce manual labor, and improve efficiency.

2. The tracked conveyor system has high stability and smooth operation.

3. Using a high-speed rotating shotblaster to spray steel balls onto the surface of the workpiece can effectively remove surface contaminants such as oxide skin and rust, resulting in a thorough cleaning of the workpiece surface.

Scope of application:

Castings, forgings, welded parts, nonbrittle parts that are prone to rolling, falling, and not easily crushed, as well as castings, aluminum castings, or certain non-ferrous metal workpieces with shallow cavities.

🔹Hanger blasting machine

Features and scope of application:

This series is a hook shot blasting cleaning machine, mainly used for surface cleaning of castings, structural components, non-ferrous alloy parts, and other parts. This series of shot blasting cleaning machines is divided into single hook, double hook, lifting, nonlifting, and other models. It has the advantages of no pit, compact structure, and high productivity.

Why Prices Can Vary Between Manufacturers

Multiple manufacturers of shot blasting machines present substantial differences in their market prices. But why?

- Equipment constructed with thicker steel components and premium materials costs more at first, but delivers extended operational periods.

- A machine with no after-sales support becomes more expensive in the long run than a machine with a low price and technical support.

- Safety & Compliance: Certified machines that meet CE or ISO standards may have a slightly higher price, but offer peace of mind.

- Machines produced in areas with high labor expenses become more costly to purchase.

At Taisheng Machinery, we believe in delivering value, not just a price tag. Our machines are designed for durability, built with quality materials, and backed by a global service team.

What to Consider Before Buying a Shot Blasting Machine

Purchasing a shot blasting machine requires considerations beyond its technical specifications and price point. Ask yourself:

- What material and surface finish do I need?

- The machine usage rate will determine its frequency of operation.

- Dust control stands as a fundamental requirement in my workplace operations.

- A manual or automated system choice falls under my requirements.

- The maintenance operations and spare part management procedures I need to establish are what I need to consider.

Every process receives guidance from our team.

We will assist you through the entire process, starting with blasting media selection, followed by installation support.

We have everything you need.

Top Features of Taisheng Shot Blasting Machines

Why do clients across 30+ countries choose Taisheng?

🔹 Compliance with Global Environmental Standards

The equipment includes high-efficiency dust collectors that fulfill CE, OSHA, and local environmental standards. The system provides clean air emissions and protects worker health, which makes it suitable for Europe and North America, and countries with strict environmental laws.

🔹 Automated Operation to Reduce Labor Costs

The equipment includes PLC automation together with smart controls and preset programs. The machine operates best in Japan, and UK, and Australia because these countries value both precision and labor-saving features.

🔹 Heavy-Duty Build for Harsh Environments

The equipment features wear-resistant steel construction along with robust components that operate in extreme heat, humidity, and dust environments. The equipment operates best in the Middle East, Africa, and Southeast Asia regions.

🔹 Flexible Machine Configurations

The product range includes roller conveyors, hook type, tumble belt, and custom models. The equipment serves complex and large workpieces and varied workpieces in the construction, steel casting, and fabrication industries.

🔹 Energy-Saving and Abrasive Recycling Design

The blast wheels operate at optimal levels, and VFD control and media reclaim systems decrease energy consumption and abrasive usage, which benefits companies by lowering operational costs and carbon emissions in eco-conscious markets.

Let’s Find the Right Machine for Your Business

The acquisition of a shot blasting machine requires substantial consideration because it represents a major purchase decision. A purchasing shot blasting machine requires more than cost information because you require specialized guidance and dependable technical backing, as well as equipment suited to your production workflow.

Please share details about your project so we can offer a customized solution that suits your specific needs.

]]>Still scrubbing away rust, grease, or flaky paint with wire brushes and toxic chemicals? Spending endless hours trying to restore metal parts—only to end up with uneven finishes and a dusty mess?

There’s a better way.

Say hello to vapor blasting—a powerful, eco-friendly, and precise method of surface preparation that’s quickly becoming the go-to choice in industries from automotive restoration to aerospace engineering.

In this guide, we’ll cover everything you need to know about vapor blasting, how it works, where it’s used, and why it may be the smartest surface finishing solution for your business. If you’re searching for vapor blasting near me, you’re in the right place.

What Is Vapor Blasting?

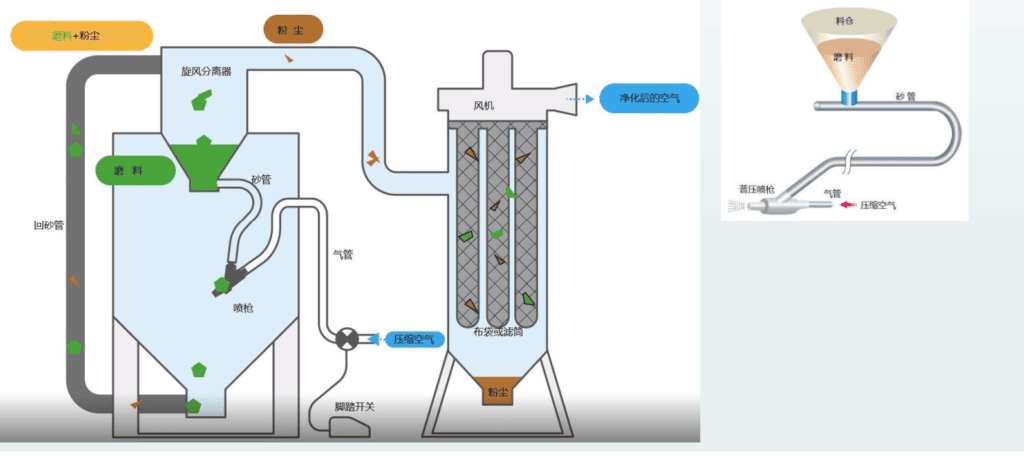

The advanced cleaning method of vapor blasting (also known as vapour blasting or wet blasting) uses abrasive media combined with water and compressed air to refine and clean surfaces. Vapor blasting machines operate without generating substantial dust or friction, enabling their use on delicate components and precise work applications.

The process operates as dustless vapor blasting since it minimizes airborne particles, protecting workers and environmental conditions.

How Does Vapor Blasting Work?

Any vapor blasting machine relies on a sophisticated technology combination:

● The vapor blasting water pump unites water with abrasive media.

● The compressed air system drives the slurry through a nozzle.

● A gentle procedure uses the mixture to eliminate contaminants and oxidation, paint, and coatings without harming the base material.

Water acts as a protective barrier between abrasive forces, so the final finish becomes more even than traditional dry blasting methods.

The results achieved through vapor blasts before and after treatment produce truly exceptional outcomes. Your components can achieve a brand-new appearance without sustaining any surface damage.

Applications of Vapor Blasting

Ready to tackle surface contaminants like a pro? Vapor blasting is a game-changer. With its ability to combine water and abrasives while adjusting pressure levels, it offers a powerful yet gentle cleaning solution for countless industries. Whether you’re restoring a classic car or prepping industrial equipment, here’s how vapor blasting shines in real-world scenarios.

Automotive Restoration

Bringing old vehicles back to life? The process allows complete removal of paint along with rust, primer, and filler through one single operation. The water component in this process prevents surface warping which traditional sandblasting often causes. The process produces smooth surfaces that are ready for primer application without damaging sensitive metals.

The best part? You can do it all with a compact vapor blaster cabinet—ideal for restoration shops and mobile setups.

Marine Maintenance

Vapor blasting provides high-quality maintenance services to fiberglass hulls and aluminum boat components. The system decreases airborne dust and simplifies cleaning operations, especially in waterfront areas. It excels at uncovering concealed blister damage and restoring older ships with fresh surfaces.

Concrete Resurfacing

Need to remove stains, sealers, or multiple layers of paint from concrete? The best approach is dustless vapor blasting. Dry blasting poses safety risks since concrete contains silica. The combination of dust reduction and cleaning performance makes this method ideal for construction environments.

Pool Restoration

This method gives your pool multiple renewal options. Remove thick paint or plaster layers, or gently clean tiles using adjustable pressures and softer abrasives—without damage or mess. For contractors, this means faster turnarounds and safer working conditions using vapor blasting equipment.

Powder Coat Removal

Forget heat guns and scraping sticky residue. Vapor blasting cools the surface, turning coatings brittle and easy to remove. Whether you’re dealing with automotive parts or aluminum panels, it’s the cleanest way to prep for repainting.

Other Handy Applications

Vapor blasting isn’t just for big jobs. It’s also a go-to for:

● Graffiti removal

● Epoxy and coating removal

● Cleaning wood, brick, stone, boats, machinery, antiques, and more

● Eliminating grime, grease, mold, calcium, corrosion, and other tough residues

Why Choose Vapor Blasting?

Because it’s effective, environmentally safe, and surface-friendly. The precision and power of vapor blasting make it the top choice for contractors, restoration specialists, and maintenance professionals who require results without the mess.

Whether you use a vapor blaster cabinet or a full-scale system, Taisheng’s vapor blasting equipment delivers the performance you can rely on.

Benefits of Vapor Blasting

● Dustless Operation: Say goodbye to messy, hazardous environments.

● Eco-Friendly: Uses water instead of harsh chemicals.

● Surface Preservation: No warping or distortion, even on thin or soft metals.

● Better Visibility: Water keeps abrasive particles contained, improving blasting visibility.

● Improved Finish: Produces a clean, matte surface ideal for painting or coating.

For manufacturers and repair shops, this translates to:

● Higher efficiency

● Reduced rework

● Lower operational costs

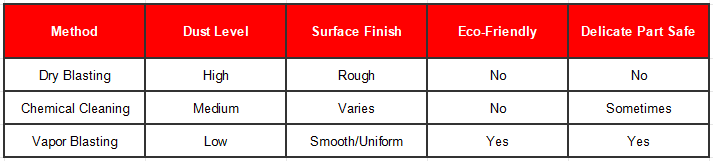

Vapor Blasting vs. Other Methods

Let’s quickly compare vapor blasting with traditional alternatives:

Vapor blasting stands out for its ability to clean with care.

Which Vapor Blasting Machine Is Right for You?

If you work in:

● Automotive

● Aerospace

● Electronics

● Metalworking

● Medical equipment

Then vapor blasting may be exactly what you need. It’s especially valuable for high-value, delicate parts and when uniform surface finishes are required.

Using a system that’s too large or small wastes time, energy, and compressed air. That’s why Taisheng offers a full range of vapor blasting machines, including mobile models and vapor blaster cabinets.

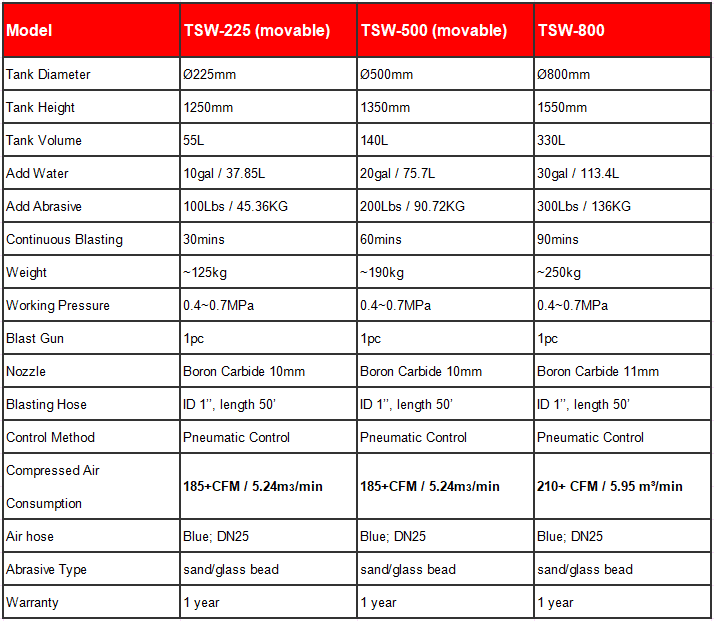

Taisheng Vapor Blasting Models at a Glance

Below is a side-by-side comparison of our TSW-225, TSW-500, and TSW-800 mobile vapor blasting units. Find the perfect match for your job.

Real-World Results: Vapor Blast Before and After

Seeing is believing. Our client’s report:

● Up to 60% faster cleaning times

● Longer equipment life through non-destructive cleaning

● Lower fatigue, better health compliance

Before: Corroded, unusable parts

After: Clean, functional, finish-ready

That’s the vapor blast before and after difference.

Ready to Upgrade Your Surface Cleaning?

Still, using outdated or damaging methods?

Vapor blasting gives you a smarter, safer, and more effective solution. Whether you’re searching for vapor blasting near me or looking to build your setup, Taisheng’s vapor blasting equipment is engineered to meet your toughest surface prep demands.

Let’s talk! Send us a message today—we’ll help you upgrade your workflow and results.

Vapor blasting is just one of many methods in the world of surface treatment. If you’re curious about other techniques, equipment specs, or process planning, here are some expert resources from our team:

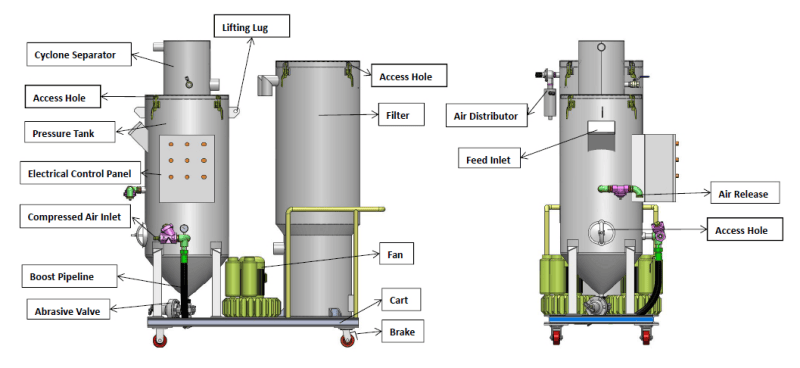

]]>A dependable dust collector system serves as an absolute necessity for present-day industrial facilities. This article explains what dust collectors are and their necessity and describes their role in developing safer, more efficient, and cleaner workspaces.

Let’s dive in.

What Is a Dust Collector System?

The equipment functions as a dust removal device that extracts airborne dust and fine particles from industrial settings before it performs filtration and collection operations. These dust collecting systems function to prevent dangerous dust from reaching workers’ machinery and products.

The following industries frequently implement these systems:

- Sandblasting and shot-blasting booths

- Metal finishing and polishing workshops

- Woodworking, foundries, cement, and chemical industries

Your application determines the need for customized dust collecting systems with filter options and air volume and collection method specifications.

The Importance of Installing a Dust Collector System in Your Workshop

The absence of a dust collector system results in a fast accumulation of dust on machinery and surfaces.

Dust exposure at work causes breathing problems and skin irritation.

The failure to meet regulatory standards becomes a compliance issue when following OSHA or CE requirements.

The combination of fine metal and chemical dust creates fire or explosion dangers.

The spread of airborne dust through masks cannot prevent it from settling in hidden areas and it continues to affect equipment functionality.

A correct dust collecting system provides several advantages through its operations:

- Remove dust at the source

- The indoor environment becomes healthier when this system is properly implemented.

- The system ensures that your final products will have consistent quality standards.

- Protect both employees and equipment

- Your workshop benefits from a silent dust-collecting system that operates behind the scenes to maintain cleanliness and operational efficiency.

Benefits of Using an Industrial Dust Collector System

The implementation of high-quality industrial dust collector systems produces the following results:

✅ Cleaner Work Environment

The environment remains clean because fine dust no longer collects on surfaces. Your workplace appears professional while remaining healthy.

✅ Protects Workers’ Health

The exposure of employees to dangerous particles decreases thus reducing their chances of respiratory problems and absence from work.

✅ Improves Machine Performance

The presence of dust particles results in damage to sensitive equipment through abrasion and blockages in critical components. A well-kept environment requires less maintenance and reduces the need for system downtime.

✅ Saves Operational Costs

The system reduces maintenance requirements while minimizing equipment damage and extending the useful life of HVAC filter components.

✅ Reduces Explosion Risks

Proper dust removal equipment installation becomes essential for protecting personnel when handling combustible materials.

How to Choose the Right Dust Collector System

Not all dust collector systems are the same. The selection of an appropriate dust collector system depends on your workplace materials and operational conditions.

The following factors need evaluation for dust collector system selection:

- Dust Type: Fine powder or heavy abrasive? Each needs different filters.

- The operation requires air volume (CFM) matching capabilities from the system.

- Filtration Level: HEPA, cartridge, baghouse? Choose equipment that fulfills your specific air purity requirements.

- Automation & Control: Do you need automatic pulse cleaning or basic manual control?

- Space & Layout: Some industries need a compact unit, others a fully centralized system.

At Taisheng Machinery, we create personalized industrial dust collector systems that meet both your process requirements and industrial standards.

Where Are Dust Collectors Used?

Our sandblasting shot blasting, and surface finishing operations require dust-collecting systems for success.

For example:

- We deploy cyclone separators together with pulse jet filters for instant dust collection in automated sandblasting rooms.

- The use of sealed dust removal equipment becomes necessary for protecting sensitive components in precise electronic systems.

- We construct heavy-duty baghouse systems for managing large dust volumes in heavy steel processing operations.

- We provide complete after-sales support and equipment guidance for all our projects because every operation requires its distinct solutions.

Final Thoughts: Let’s Make Your Workshop Safer and Cleaner

A dust collector system represents a sound investment when employee health matters or you aim to enhance product quality or satisfy compliance requirements.

Since 2007, Taisheng has operated with over 18 year of metal surface treatment experience, which includes integrating dust removal equipment. Our company focuses on machine sales while providing customers with personalized, safe, reliable, and efficient solution development.

Are you uncertain about which system matches your workshop requirements?

Reach out to us through a message so we can assist in finding the most suitable solution for your production process.

At Taisheng Machinery, we’ve helped industries around the world improve their processes with high-performance sandblasting systems and a wide range of sandblaster media. In this guide, we’ll explain what sandblasting media is, the different types available, and how to choose the most effective abrasive for your job.

What Is Sandblasting?

Sandblasting, also known as abrasive blasting, is a process that propels sand blasting media at high speed onto a surface to clean, texture, or prepare it. The impact of the media removes rust, old coatings, contaminants, or other surface imperfections.

Common applications of sandblasting include:

- Rust and paint removal

- Surface cleaning

- Creating texture

- Preparing surfaces before painting, bonding, or coating

The type of sandblast finish you achieve—smooth, matte, or coarse—depends heavily on the abrasive you select. This technique is widely used in sectors like automotive, aerospace, construction, and precision electronics.

What Is Sandblasting Media?

The blasting media is the material used in the sandblasting process to clean or finish a surface. Though originally sand was commonly used, today’s industry offers a variety of safer, more efficient alternatives depending on the desired outcome.

Media is the heart of any sandblasting process. It affects:

- The finish of your surface

- The efficiency of the operation

- The health and safety of your workers

- The operating cost of your process

Understanding which media to choose is essential for achieving your production goals — and protecting both your equipment and your team.

Common Types of Sandblasting Media (with Pros & Cons)

Here are 8 of the most commonly used sandblasting media and when to use them:

1. Garnet

Garnet is a natural, hard, and eco-friendly sandblasting media that’s ideal for high-speed surface cleaning and precise surface preparation. Known for its sharp edges and low dust generation, garnet blasting media cuts through rust, paint, and scale efficiently without harming the base material. It’s widely used in shipbuilding, oil & gas maintenance, and waterjet cutting due to its recyclability and consistent performance. For projects that demand both power and cleanliness, garnet remains a top choice among modern sandblasting media options.

Best for: Heavy-duty surface cleaning, shipbuilding, steel prep

Pros: Recyclable, eco-friendly, fast cutting

Cons: Higher initial cost

Garnet is sharp, reusable, and excellent for industrial metal cleaning.

2. Glass Beads

Glass beads are a popular abrasive media in sandblasting, especially when you need a smooth, satin sand blast finish without damaging the material. For gentle cleaning and surface preparation, glass bead blasting works well on metals, plastics, and even delicate parts. Unlike harsher abrasives, glass beads clean the surface while maintaining the original dimensions and integrity of the workpiece. This makes them perfect for applications that require precision and a clean, polished look.

Best for: Stainless steel, aluminum finishing

Pros: Smooth satin finish, reusable

Cons: Less aggressive

It is ideal for cleaning and polishing surfaces without changing their shape or dimension.

3. Aluminum Oxide

Brown Aluminum Oxide (Al₂O₃) is a tough, long-lasting abrasive that’s perfect for aggressive surface cleaning and preparation. Its hardness and durability make it ideal for quickly removing rust, paint, and other contaminants during the sandblast process, helping you achieve a clean, roughened surface that’s ready for coating or finishing. Whether you’re working with metal, stone, or composites, aluminum oxide blasting media ensures fast, consistent results.

Best for: Paint removal, surface profiling

Pros: Very hard, fast cutting, reusable

Cons: Generates more dust

Great for aggressive cleaning and etching — but requires good dust collection.

4. Steel Shot & Grit

Steel shot is a high-performance abrasive commonly used in industrial shot blasting for surface cleaning and shot peening. Known for its strength and durability, steel shot delivers consistent results, making it ideal for heavy-duty applications such as cleaning castings, forgings, and steel structures. It helps improve fatigue resistance in metal parts while leaving a smooth, polished surface ready for further treatment.

Steel grit is a sharp, angular abrasive that provides aggressive cleaning power—perfect for removing rust, old paint, and scale from metal surfaces. It cuts through tough coatings quickly, leaving a rough profile ideal for coating adhesion or further processing. Whether you’re working in shipyards, foundries, or fabrication shops, steel grit blasting media is the go-to solution for efficient, deep surface preparation.

Best for: Foundries, automotive parts, heavy machinery

Pros: Durable, fast cleaning, reusable

Cons: Requires heavy-duty blasting equipment

Steel abrasives are excellent for mass-production environments.

5. Silicon Carbide

Silicon carbide is one of the hardest sandblasting media available, ideal for precision surface treatment where speed and cutting power matter. Its sharp, angular particles make it perfect for removing tough coatings, rust, or scale from hard materials like ceramics, glass, and hardened steel. Silicon carbide blasting delivers a highly consistent surface profile, making it a go-to choice for applications that demand aggressive cleaning and fine detail. Plus, its high thermal conductivity and chemical stability ensure excellent performance in demanding environments.

Best for: Precision tools, electronics

Pros: Extremely hard, fast cutting

Cons: Expensive

Ideal when you need aggressive cutting for very hard surfaces.

6. Walnut Shells

Walnut shell is a natural, biodegradable sandblaster media that’s perfect for gentle surface cleaning, polishing, and light surface preparation. Its soft yet effective texture makes it safe for use on delicate surfaces like wood, aluminum, fiberglass, and even historic artifacts. Walnut shell blasting is commonly used when you need to clean without etching or damaging the underlying material—making it an excellent eco-friendly choice for precision work.

Best for: Delicate substrates like wood, plastics, aircraft

Pros: Biodegradable, gentle cleaning

Cons: Not effective on hard metals

Used where surface integrity is critical, such as historical restorations.

7. Plastic Beads

Plastic beads are a lightweight, non-abrasive sandblasting media designed for delicate surface cleaning and paint removal without damaging the underlying material. Ideal for applications involving aluminum, composites, plastics, and soft metals, plastic bead sandblasting is commonly used in aerospace, automotive, and electronics industries. Their low hardness makes them perfect for stripping coatings while preserving fine details and surface integrity—especially when working with precision components or sensitive parts.

Best for: Automotive paint stripping, aerospace

Pros: Won’t damage soft materials

Cons: Limited cutting power

Perfect for removing coatings from delicate surfaces like composites.

8. Ceramic Beads

Ceramic beads are a premium sandblasting media known for their durability and high-performance surface finishing. Ideal for applications requiring tough yet precise cleaning and polishing, ceramic bead sandblasting media delivers consistent results without contaminating the workpiece. These beads are perfect for stainless steel, titanium, and other high-value materials where a smooth, uniform finish is critical. Their long lifespan and stable performance make them a cost-effective choice for demanding surface treatment tasks.

Best for: Aerospace, medical, precision electronics

Pros: Consistent finish, low dust, non-contaminating

Cons: Higher price

Provides excellent repeatability and cleanliness — ideal for cleanroom applications.

How to Choose the Right Sandblasting Media

Choosing the right sandblasting media is key to getting the finish you want without damaging the surface. Different projects require different sandblaster media, depending on the material you’re working with and the result you’re aiming for. For example, if you’re cleaning rust off heavy steel parts, a hard abrasive like aluminum oxide or steel grit might be best. But if you’re restoring delicate surfaces like soft metals or wood, gentler options such as glass beads or walnut shells are safer and more effective.

Think about three main factors:

- Surface Material – Is it hard metal, soft aluminum, wood, or plastic?

- Desired Sand Blast Finish – Do you want a rough profile for coating, or a smooth, polished look?

- Application Goal – Are you cleaning, etching, polishing, or preparing for painting?

If you’re not sure how to sandblast or which sandblasting media is best for your application, don’t worry—we’re here to help. At Taisheng Machinery, we understand that choosing the right sandblaster media can be confusing, especially with so many options available. Feel free to contact our expert team for advice. Send us an inquiry with details about your material and blasting goals, and we’ll recommend the most suitable abrasive to ensure optimal results while protecting your equipment and reducing your operating costs.

Why Safety and Dust Control Matter

Blasting with inappropriate or outdated media — like silica sand — can pose serious health risks, including silicosis and respiratory problems. That’s why many countries have banned it.

At Taisheng, we provide environmentally safe media and dust-free blasting systems to protect your team and ensure workplace compliance.

Our systems are equipped with high-performance dust collectors, air filters, and closed-loop recycling options, ensuring your process is clean, efficient, and regulation-friendly.

Complete Sandblasting Solutions from Taisheng Machinery

Choosing the right media is just the beginning. At Changzhou Taisheng Machinery Co., Ltd., we go beyond just selling products — we provide:

- Customized sandblasting machines

- Full range of abrasive blasting media

- Precision-engineered blast rooms and recovery systems

- Industrial dust collectors

- After-sales training and global service

We’ve proudly served major global clients in aerospace, automotive, oil pipelines, metal fabrication, and more — exporting to over 30 countries, including the USA, Japan, and the UK.

Let’s Work Together

Sandblasting is a powerful process — but only if you choose the right tools and media. With Taisheng, you’re not just getting equipment. You’re getting a partner who understands your challenges and works with you to solve them.

The right media can extend your machine’s life, reduce costs, and improve product quality. Whether you’re cleaning heavy steel plates or polishing intricate parts, we’re here to help you do it right — every time.

Let us help you achieve the perfect finish. contact me!

]]>In this article, we’ll walk you through the most common metal finishing types, their pros and cons, and help you choose what works best. Whether you’re preparing metal surfaces for painting, protecting them from rust, or just improving their appearance—this guide is for you.

What Is Metal Finishing and Why It Matters

Metal finishing refers to the surface modification process that includes protective coatings and treatments applied to metal components to enhance their appearance and functional performance. The finishing methods include cleaning, followed by polishing, plating, blasting, and coating, according to the required purpose and performance needs.

Common benefits of metal finishing include:

- Protection against rust, wear, and corrosion

- Improved electrical conductivity

- Aesthetic appeal (smooth, glossy, or matte surfaces)

- Easier cleaning and maintenance

The manufacturing process of metal finishing applies across multiple industries including automotive, aerospace, electronics, construction, and precision manufacturing sectors.

The Main Types of Metal Finishes (With Pros & Cons)

Here’s a closer look at some of the most popular metal finish types used across industries today:

1. Sandblasting

Sandblasting operates as a mechanical system that uses compressed air to propel abrasive materials (steel grit, glass beads, or garnet) at surfaces. The procedure removes rust, paint, or scale while producing an appropriate rough surface for painting or coating purposes.

Best for: Surface preparation before painting, removing rust or contaminants

Pros:

✅ Environmentally friendly (no chemicals)

✅ Works on large surfaces

✅ Efficient and cost-effective

Cons: Requires dust control systems

2. Shot Blasting

High-speed metal pellets, known as shots, are propelled against metal surfaces to clean them and provide structural reinforcement. This method is primarily used in heavy industry for cleaning large metal structures.

Best for: Heavy-duty cleaning of steel, castings, pipelines

Pros:

✅ Fast cleaning for large volumes

✅ Strengthens surfaces (peening effect)

✅ Reduces fatigue in metal parts

Cons: Higher upfront equipment cost

Need industrial sandblasting equipment? We manufacture reliable, energy-efficient blasting machines—designed for long-term use.

3. Powder Coating

In powder coating the finishing process, powdered materials consisting of resin and pigments are heated to form solid coatings on metal surfaces after spraying.

Best for: Decorative finishes on furniture, appliances, tools

Pros:

✅ Durable and chip-resistant

✅ No solvents or VOCs

✅ Wide range of colors and textures

Cons: Not suitable for heat-sensitive parts

4. Electroplating

Electroplating works through electrical current deposition to apply zinc, nickel, or chrome layers onto different metal surfaces.

Best for: Corrosion protection, decorative metal parts

Pros:

✅ Uniform coating

✅ Improves electrical conductivity

✅ Attractive finish

Cons: Involves hazardous chemicals

5. Anodizing

Anodizing is mainly used for aluminum. The electrochemical process produces an extensive oxide layer that protects the material.

Best for: Aluminum parts that need durability and color

Pros:

✅ Excellent corrosion resistance

✅ Can be dyed in various colors

✅ Hard and long-lasting

Cons: Limited to aluminum and titanium

6. Polishing and Buffing

The mechanical treatment of metal surfaces through polishing and buffing creates mirror-like reflective surfaces.

Best for: Stainless steel, decorative parts, medical equipment

Pros:

✅ High-end, premium look

✅ Removes scratches and imperfections

Cons: Surface can still be prone to rust without further treatment

How to Choose the Right Metal Finish for Your Application

Not sure which finish to choose? Here are some key points to consider:

- Material type: Aluminum, steel, or stainless steel

- End-use environment: Indoor, outdoor, high heat, marine, etc.

- Durability needs: Scratch resistance, corrosion protection, UV exposure

- Appearance: Matte, gloss, color options

- Volume and scale: Single parts or mass production

- Maintenance cost: Long-term cleaning and upkeep

As a B2B business, you need to calculate the complete operating expenses which include utility costs together with materials usage and safety equipment maintenance.

Still unsure? We will select the most suitable option based on the characteristics of your components and operational requirements.

Why Choose Us for Surface Finishing Equipment

Since 2007 our company at Taisheng Machinery has provided metal finishing improvements to our customers. Our manufacturing operations create high-performance sandblasting machines and shot blasting systems together with dust collectors and full custom solutions which we export to 30+ countries including the USA, UK, and Japan.

What makes us different?

- Over 15 years of experience in metal surface treatment

- Strong R&D and high-efficiency machines

- Durable, energy-saving, and eco-friendly designs

- Full after-sales support, spare parts, and technical service

Let’s Talk: We’re Here to Help

The process of selecting suitable metal finishing methods should not be complicated. Our staff will help you find the ideal solution regardless of whether you work with small precise components or big industrial machinery.

Do you have questions regarding your current project? Our team will provide you with expert guidance along with a complimentary price quote which we will send within 24 hours. Contact Us Now!

]]>What Is Abrasive Sandblasting?

The process of abrasive sandblasting which is known as sandblasting uses abrasive materials accelerated at high speed to clean etch or texture mainly metal surfaces. The term “sandblasting” suggests the use of sand; modern applications often use alternative media like steel grit, glass beads, aluminum oxide, walnut shells, or ceramic grit, depending on the finish required and environmental regulations.

This process is highly effective for removing rust, paint, scale, or other surface contaminants, and preparing parts for coating or welding. It’s widely used in industries such as construction, automotive, aerospace, and heavy manufacturing.

Taisheng Machinery designs automated sandblasting systems that improve efficiency and produce uniform surface treatment and safe working environments. Our solutions focus on environmental protection and worker health, with enclosed systems and dust collectors that reduce airborne particles and noise.

What Is Abrasive Blasting?

Abrasive blasting refers to any blasting technique that employs abrasive materials to modify or clean surfaces. This includes abrasive blast cleaning, grit blasting, and micro-abrasive blasting. Unlike traditional sandblasting, abrasive blasting covers a variety of techniques tailored for specific materials, including heat-sensitive or intricate components.

This process can be used for precise shaping, surface texturing, or edge profiling, making it ideal for electronics, aerospace components, and delicate assemblies. The abrasives used vary in hardness and size, allowing a high degree of customization.

Our precision abrasive blasting equipment offers excellent control and adaptability, ensuring that even complex components receive uniform treatment without compromising integrity.

Abrasive Blasting vs. Sandblasting: How Do They Differ?

While the terms overlap, here’s a breakdown of their key differences:

| Feature | Sandblasting | Abrasive Blasting |

| Media | Traditionally silica sand | Wide range of media types |

| Health & Safety | Risk of silicosis | Media selected for safety & performance |

| Terminology | Outdated but widely used | Modern, technically accurate |

| Flexibility | Limited by sand properties | Tailored to specific applications |

In short: All sandblasting is abrasive blasting, but not all abrasive blasting is sandblasting.

Which Blasting Process Is Right for Your Project?

At Changzhou Taisheng Machinery, we understand that choosing the right surface treatment method is crucial for your business. Whether you’re focused on improving production speed, extending the life of your equipment, or ensuring safety for your workers, we’re here to help you find the most efficient and cost-effective solution. Our team offers personalized advice to make sure you choose the best blasting method for your unique needs. If you’re unsure whether sandblasting, abrasive blasting or another method is right for your project, feel free to reach out to us. We’re ready to provide expert guidance and support to help you make the best decision.

Common Types of Abrasive Blasting

We produce and distribute systems for all primary blasting procedures at Taisheng Machinery:

Manual Sandblaster

The manual sandblaster uses compressed air to launch abrasive blasting media consisting of sand or grit to clean or prepare surfaces. The method proves best for small-scale projects that demand precision because operators manually control the flow and pressure. This equipment operates in abrasive blast cleaning applications to eliminate rust, scale, or old coatings from metal, concrete, or stone.

Main Features of the Manual Sandblaster Cabinet:

- Easy loading with a right-side door.

- Scratch-resistant LED lighting for clear visibility.

- Foot pedal control for hands-free blasting.

Applications of the Manual Sandblaster Cabinet:

- Provides uniform satin finishes on various metals.

- Removes rust, scale, and carbon from metals.

- Strips paint and coatings for rework.

Main Features of the Vacuum Blasting Machine:

• Eco-friendly design: Automatic sand, rust, and dust recovery, with a 99% sand recovery rate.

• Adjustable working radius to suit different worksite needs, with surface treatment levels reaching Sa2.5-3.

• Portable car-type box structure: Rainproof, dustproof, and easy to move.

• Automatic sand circulation and dust filtration for a clean, pollution-free environment, meeting GB103328-10333-89 air dust hygiene standards.

Applications of the Vacuum Blasting Machine:

• It is very good at removing rust, scale, and coatings from the metals.

• Safely cleans delicate surfaces like aircraft and precision parts.

• It is used for cleaning castings, mold,s, and metal surfaces before further processing or painting.

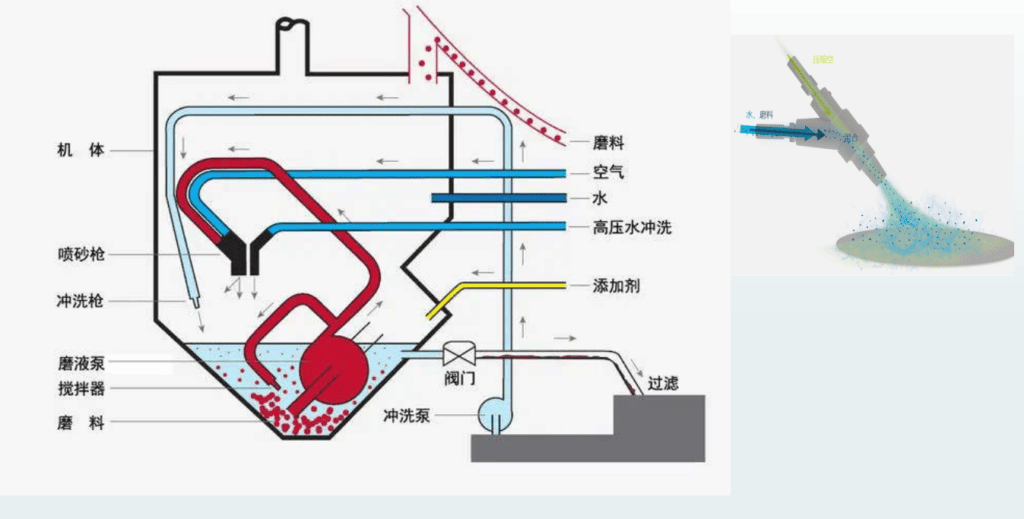

Features of the Wet Blasting Machine:

• Stainless Steel Construction: Durable and corrosion-resistant.

• Non-electric Airbag Switch: Simple, safe, and reliable control for sand pump and compressed air.

• Efficient Sand Pump: Easy to start with a long lifespan.

• Compact Design: Ideal for small to medium-sized workpieces

Applications of the Wet Blasting Machine:

• Surface Treatment: For pretreatment, matte finishing, and polishing.

• Cleaning Parts: Cleans forgings, castings, welded parts, and electrical components.

• Delicate Item Cleaning: Ideal for jewelry, crystal glass, and other sensitive materials.

• Fine Abrasives: Works best with glass beads and diamond sand for precise finishes.

Automatic Sandblaster

An automatic sandblaster is a fully automated system that performs abrasive blasting without manual intervention. It offers consistent, high-speed cleaning or surface preparation, making it ideal for industries like metalworking or “oil pipelines”. The system ensures precise results with minimal operator input, making it efficient and cost-effective.

Main Features of the Airless Blasting Machine:

• Designed to replace traditional belt conveyor sandblasting machines.

• Suitable for processing mobile phone shells, laptop covers, and other similar electronic products.

• Equipped with advanced features for high-temperature coating and plating applications.

• Ideal for treating precise electronic components like mobile phone cases, computer enclosures, and communication devices.

Applications of the Airless Blasting Machine:

• It is used for the efficient preparation of products for high-temperature coating and plating like non-stick pans and gas stove cores.

• Widely used for cleaning and surface treatment of electronic products, including mobile phones and computers.

• Perfect for products requiring precise sandblasting before further processing, such as paint or plating.

Main Features of the Conveyor Blasting Machine:

• Optimized Blast Coverage: Blast head systems are strategically positioned to ensure uniform coverage across components.

• Automatic and Energy-efficient Operation: Can interface with material handling systems for unmanned operation, with PLC control to reduce energy consumption.

• Durable Construction: Built with heavy-duty welded steel housing for long-lasting performance.

Applications of the Conveyor Blasting Machine:

• Blasts Flat and Complex Components: Perfect for plates, profiles, and various-shaped parts.

• Efficient Small Part Blasting: Ideal for high-speed blasting of small items like toasters, badges, and laptop cases.

• Treats Long Components: Suitable for processing long tube and bar materials.

• Versatile Material Use: Works effectively on stainless steel, carbon steel, aluminum, glass, and more.

Main Features of the Automatic Rotary Turntable Sand Blast Equipment:

• Automatic Rotation: Workpieces are automatically positioned for efficient blasting.

• PLC Control: Fully automated with programmable control for ease of use.

• Adjustable Gun Swing: Ensures thorough cleaning at all angles.

• Durable Construction: Built for heavy-duty, mass-production environments.

Applications of the Automatic Rotary Turntable Sand Blast Equipment:

• Mass Production: Ideal for blasting pans, cylinders, and square box-type items.

• Internal and External Blasting: Perfect for both inside and outside surfaces.

• Wide Range of Products: Works with items like electric kettles, bakeware, and stainless steel basins.

• Compatible with Various Abrasives: Suitable for aluminum oxide, glass beads, and ceramic beads.

Main Features of the Tumble Basket Sand Blasting Machine:

• The equipment performs well for cleaning small metallic pieces along with plastics and thermosetting parts.

• Automated Operation: Easy to use with adjustable basket rotation speed.

• Abrasive Recycling: Equipped with a cyclone separator for efficient abrasive usage.

• High Blasting Efficiency: A remote-controlled blasting gun ensures excellent results.

Applications of the Tumble Basket Sand Blasting Machine:

• Small Parts Cleaning: Perfect for bolts, fasteners, nuts, and tools.

• Versatile Materials: Suitable for zinc aluminum die casting, PMMA, and sintered metal products.

• Pneumatic Tools: Ideal for cleaning parts like pneumatic screwdrivers.

• Abrasive Compatibility: Works with aluminum oxide, glass beads, and zircon sand.

Main Features of the Rubber Belt Tumble Blasting Machine:

• The machine operates automatically to tumble parts for standard cleaning and finishing while users set parameters including media flow rates and blast pressures.

• Durable Rubber Lining: The machine features a rubber-lined interior to withstand years of heavy-duty cleaning and shot peening.

• Adjustable Settings: Users can control time, media type, pressure, tumble speed, and blast duration to optimize finishing results.

Applications of the Rubber Belt Tumble Blasting Machine:

• Small Parts Cleaning: Ideal for bolts, PMMA, zinc aluminum die castings, and tools.

• Versatile for Various Materials: Effective for cleaning sintered metal products and pneumatic screwdrivers.

• Abrasive Compatibility: Works with aluminum oxide, glass beads, and zircon sand for optimal results.

Mold Sandblater:

Main Features of the Tire Mold Automatic Sandblaster:

• Automated Operation: Features an electric rotating table and automatic entry/exit for efficient mold handling and consistent cleaning.

• High Capacity: Capable of handling tire molds that measure up to 1500mm in diameter and have a maximum loading capacity of 1.5 tons.

• Precise Blasting Control: Provides adjustable blasting parameters that guarantee optimal cleaning outcomes across different tire mold sizes and shapes.

The Tire Mold Automatic Sandblaster operates to eliminate rust along with dirt and contaminants from tire molds thus creating suitable conditions for additional processing or coating.

Features:

• The system efficiently removes surface impurities to boost wear resistance as well as adhesion and corrosion protection capabilities. 2. The size and hardness of the impact abrasive can be adjusted to achieve different effects.

• The equipment can efficiently handle parts that have concave or horizontal features that typical machines cannot access.

• The steel pipe and thread exhibit a matte finish which does not reflect light while the coverage reaches 100%

Suitable for sandblasting of steel pipe end threads

Our company provides advanced sandblasting machines together with Wheel Blast Machines and Sand Blast Booths which offer total surface treatment solutions. The Wheel Blast Machines operate at high efficiency for high-volume production and serve well in automotive and metalworking sectors for cleaning surface strengthening and smoothing.

Our company provides detailed information about our products that can boost your production efficiency and surface quality improvement.

How to Choose the Right Blasting Method:

The selection process for blasting solutions requires examination of three main factors:

• Material type ‒ Aluminum, steel, plastic, glass, etc.

• Finish quality ‒ Smoothness, anchor profile depth, coating compatibility

• Production scale ‒ High-volume vs. custom jobs

• Safety/environmental ‒ Dust containment, operator health, noise control

The Taisheng team specializes in creating customized equipment setups which include:

• Automatic abrasive recovery systems

• Eco-friendly, low-noise designs

• Precision control for high-tolerance parts

Why Choose Taisheng Blasting Equipment?

Since its inception nearly two decades ago Changzhou Taisheng Machinery Co., Ltd. has become the go-to surface preparation provider for major global brands across the aerospace automotive energy, and electronics industries. Our commitment to:

- Professionalism – Industry-leading engineering and R&D

- Authority – Deep expertise in surface treatment processes

- Friendliness – Personalized guidance and responsive service

- Technical Excellence – Custom-built solutions with smart automation

- After-Sales Service – Long-term maintenance and global support

ensure you get more than just a machine—you get a lasting solution.

Get Expert Help Choosing the Right Blasting Equipment

Need Help Choosing the Right Blasting Equipment?

Choosing the right blasting equipment can make all the difference in achieving the best results for your project. Whether you’re aiming to improve efficiency, lower costs, or upgrade your systems, Taisheng Machinery is here to help. Our team is ready to guide you in finding the perfect abrasive blasting solution for your needs.

Do you have questions or want to learn more? Don’t hesitate to reach out to us—we’d be happy to help!

📞 [Contact Our Team for Expert Advice]

👉 [Explore Our Blasting Equipment]

]]>What is Shot Blasting?

Shot blasting is a mechanical surface preparation method that uses high-speed abrasive particles (called ‘grits’) to clean, strengthen, or polish metal surfaces. Unlike sandblasting, which uses compressed air and a softer media, shot blasting uses harder abrasives, such as steel shot or grit, through centrifugal force. This method provides a deep, clean, consistent surface texture for heavy-duty industrial applications by removing rust, scale, and old coatings.

Why is Shot Blasting Important?

Taisheng Machinery has dedicated more than 18 years to developing surface preparation solutions that serve various global industries. Shot blasting represents a complete transformation rather than a simple procedure. Through this process, manufacturers can achieve both high efficiency and environmental sustainability, which enables them to fulfill modern quality and sustainability requirements.

Why Trust TaiSheng?

Our company has delivered shot blasting systems to Huawei, Baosteel, and CRRC, which resulted in production increases reaching 300%. This article will explain the operational aspects of this technology, together with its critical importance for your organization.

Comparison Table: Sandblasting Machine vs. Shot Blasting Machine

| Item | Sandblasting Machine | Shot Blasting Machine |

|---|---|---|

| Power Source | Compressed air | Motor-driven impeller (centrifugal force) |

| Energy Efficiency | Higher energy consumption (conversion loss) | Low energy consumption, high efficiency |

| Efficiency | Relatively low efficiency | High efficiency, suitable for mass processing |

| Application Range | Broad application, not limited by workpiece size | Suitable for large, thick workpieces with regular shapes |

| Equipment Cost | Ranges from a few thousand to over a million RMB | Higher starting cost, typically from RMB 30,000 to 50,000+ |

| Abrasive Types | Versatile: steel grit, glass beads, etc. | Limited: steel shot, ceramic beads only |

| Control Parameters | Adjustable distance, angle, and pressure | Difficult to adjust; relies on tooling and setup |

| Workpiece Adaptability | Ideal for complex structures and high-precision requirements | Not suitable for dead corners or high surface quality needs |

| Safety | Enclosed operation, high safety level | The risk of abrasive spillage requires external protection |

| Maintenance | Low wear and tear, easy maintenance | More wear parts, higher maintenance cost |

How Does the Shot Blasting Process Work?

Feeding

Workpieces are fed into the blast machine using hooks, roller conveyors, or tracks.

Blast Cleaning

A high-speed rotating blast wheel throws steel shot at the workpiece at a very high speed to remove surface corrosion, oxidised skin, or old coatings.

Separation and Recycling

The steel shot and impurities are processed through the separator and can be recycled to improve efficiency and reduce costs.

Dust removal and purification

A high-efficiency dust removal system vacuums dust in real time to ensure the clean and environmentally friendly operation of the equipment.

Discharge and Inspection

The cleaned workpieces are automatically discharged for quality inspection and can enter the next process, such as spraying or packaging.

TaiSheng Shot Blasting Equipment: Built for Excellence

The system operates with low energy usage while delivering high efficiency when handling large workpiece quantities.

The system works best with workpieces thicker than 3mm, but frequency control allows it to process workpieces down to 2mm thickness.

The equipment supports workpieces that need moderate surface roughness treatment, including castings and thick plates and profiles, and steel structures, and steel plate pretreatment.

Shot Blasting Equipment Types & Applications

| Machine Type | Best For | TaiSheng Model |

| Hanger Type Shot Blasting Machine | Surface cleaning of castings, structural parts, non-ferrous alloys, and other parts | Q375-Q3750(Single/Double Hook), etc. |

| Pass-through Shot Blasting Machine | Used in construction, bridges, and other industries, large I-beams, H-beams, and other large-sized steel structure parts | QH698 QH6912 QH6915 QH6918, etc. |

| Track Type Shot Blasting Machine | Castings, forgings, welded parts, non-brittle parts, cast aluminium parts, non-ferrous metal workpieces | Q15GNQ28GN, etc. |

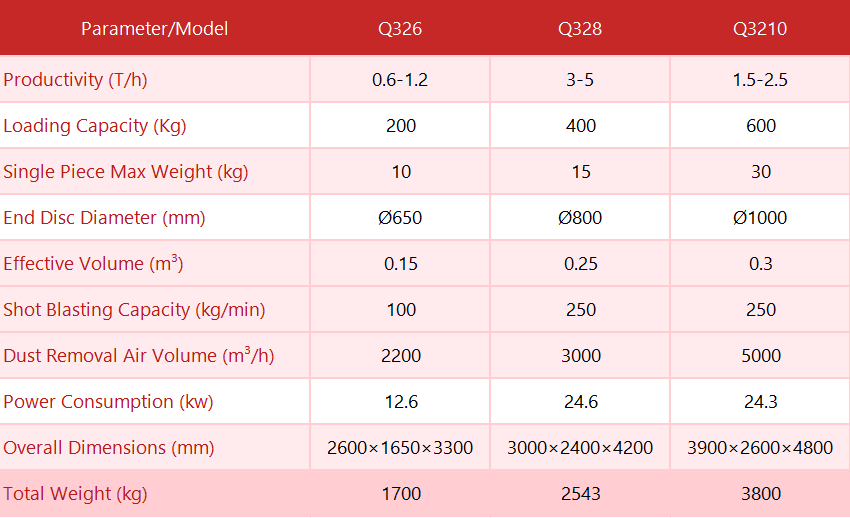

| Q32 Series Shot Blasting Machine | Small and medium-sized castings, forgings, stampings, non-ferrous castings, gears, and springs | Q326Q328Qr3210, etc. |

Key Selection Criteria:

- Abrasive Compatibility: Our engineers offer professional advice to choose the right abrasive: Steel sand (bearing steel sand)、steel shot (0.1-2mm particle size)、Ceramic beads, and glass beads (0.3-2mm particle size).

- Durability: TaiSheng machines operate for 100,000+ hours (industry average: 60,000 hours).

- Superior Cost Efficiency: Our modular spare parts design reduces replacement frequency and labor downtime, which results in $5,000 annual savings on maintenance costs.

Applications of shot blast cleaning in Industry: Where TaiSheng Excels

- Automotive & Aerospace

The cleaning process of engine blocks, gears, and aircraft components is through surface cleaning.

- Foundry & Metalworking

The removal of casting residues, oxide layers, and heat treatment scale.

- Pipeline & Construction

The removal of rust and surface preparation for pipeline anti-corrosion coating.

- Precision Electronics & Optics

High-precision surface finishing for aluminum and stainless steel parts.

Real Customer Stories: Why Big Companies Choose Our Shot Blasting:

At Taisheng Machinery, we’re proud to work with some of the top manufacturers in China. Here are two real examples that show how our machines help big clients improve their production.

1. Shilin Auto Parts – Hook Type Shot Blasting Machine for Aluminum Castings

Shilin is a well-known auto parts supplier with very high standards. They needed a reliable machine to clean and strengthen aluminum die-cast parts. We provided them with a hook-type shot blasting machine that’s powerful, easy to operate, and gives a smooth, even finish. It helped boost their production efficiency and product quality.

2. Jiangyin Quanhua Feng Forging – Tumble Belt Shot Blasting Machine for Forged Parts

Quanhua Feng needed a heavy-duty machine to handle large batches of forged parts. Our tumble belt shot blasting machine was the perfect fit. It uses wear-resistant manganese steel and a high-performance blast wheel, which means it lasts longer and cleans faster. The result? Less downtime, lower maintenance costs, and higher output.

These cases show how we support different industries with custom solutions. Whether it’s for aluminum castings, forged parts, or other materials, we’re ready to help you find the right machine for your needs.

Want to know how we can help your business, too?

👉 Contact us today for a free consultation.

FAQs: Answering Your Top Concerns

Q: What materials are used for shot blasting?

Shot blasting uses steel shot, steel grit, aluminum oxide, ceramic beads, and glass beads, depending on the application and surface requirements.

Q: Is shot blasting effective?

A: Yes, shot blasting is very effective at removing rust, oxidation, and old coatings, leaving a clean surface that helps new coatings stick better.

Q: Is shot blasting easy to operate?

A: Most shot blasting machines are automatic or semi-automatic and can be operated with basic training by following standard procedures.

Q: What is the job of a blast operator?

A: A blast operator runs the machine to clean or prepare metal surfaces using high-speed abrasive blasting based on the required process.

Q: What exactly does shot blasting service involve?

A: Shot blasting services provide custom cleaning or surface treatment solutions based on the type of material, size of the workpiece, and surface condition.

Q: How much does shot blasting cost?

A: Shot blasting is usually charged by square meter, and the price ranges from a few dollars to over a hundred, depending on the job complexity and surface condition.

Q: Can shot blasting remove rust?

A: Yes, shot blasting is a great way to remove rust, scale, and dirt, making the metal clean and ready for painting or coating.

Conclusion: Elevate Your Surface Prep with TaiSheng

If you need a reliable, scalable, and cost-effective surface treatment process, shot blasting is a solution worth considering. Whether you handle small precision components or massive steel beams, Taisheng Machinery offers tailored equipment and expert guidance to help you get the job done right.

📩 Ready to improve your surface preparation process? Contact us today to speak with our specialists.

]]>Sandblasting, also known as abrasive blasting, is a fundamental process in surface preparation, widely utilized across various industries to clean, smooth, or roughen surfaces by propelling abrasive materials under high pressure. Understanding the mechanics of a sandblaster is essential for selecting the appropriate equipment and achieving optimal results.

In this blog, we will unravel the mystery of sandblasting machines and delve into their working principles, application scenarios, and why you should choose Taisheng sandblasting machines. By analyzing the core strengths of Taisheng’s sandblasting machines, we will reveal why they are the equipment of choice for so many companies. We will also explore the driving factors behind the growing popularity of sandblasting machines in the industrial sector. Join us for an in-depth look at the appeal of sandblasting technology and the excellence of Taisheng’s sandblasting machines!

What is a Sandblaster?

A sandblaster (or sandblasting machine) is a compressed air-powered, high-speed jet beam that sprays sand at high speed into the exterior of the workpiece to be processed by a rubberized sand hose gun. The core components of a typical sandblasting system include:

●Abrasive Media Tank: Stores the chosen abrasive material, such as aluminum oxide, steel grit, or glass beads.

●Air Compressor: Generates the high-pressure air required to propel the abrasive media.

●Blast Hose and Nozzle: Directs the high-velocity abrasive stream onto the target surface.

●Dust Collection System: Captures residual dust and debris, maintaining a clean work environment and facilitating the recycling of abrasive materials.

How Does a Sandblaster Work?

The sandblasting process involves several key steps:

1. Abrasive Media Loading: The selected abrasive material is loaded into the media tank.

2. Air Compression: An air compressor pressurizes air to the required levels for effective blasting.

3 . Abrasive Flow Control: A metering valve regulates the flow of abrasive media into the blast hose, ensuring consistent delivery.

4. Surface Impact: The abrasive particles, propelled at high velocity, impact the surface to remove rust, paint, or other unwanted materials.

5. Dust & Media Collection: A dust collection system captures spent abrasive and debris, minimizing environmental contamination and allowing for the recycling of media.

What is a Sandblaster Used For?

Sandblasters are versatile tools with applications across various industries:

●Industrial Cleaning: Removing rust, paint, and coatings from metal surfaces to prepare them for further processing or finishing.

●Surface Preparation: Creating a suitable profile on surfaces before applying paints, coatings, or adhesives, ensuring better adhesion and longevity.

●Automotive Industry: Stripping old paint and corrosion from vehicle bodies and parts, facilitating restoration and repainting.

●Construction & Restoration: Cleaning and restoring brick, stone, and concrete structures by removing grime, graffiti, or old paint.

●Precision Etching: Engraving detailed designs on materials like glass, stone, or metal for artistic or functional purposes.

After understanding the basic principles and wide range of applications of sandblasting machines, you may wonder: among many brands, why does the Taisheng sandblasting machine stand out? Next, we will take you into the world of the Taisheng sand blast machine!

Types of Taisheng sand blasting machines:

Taisheng Machinery has been committed to the sandblasting machine industry for 18 years and can provide you with different types of sand-blasting machines according to your specific applications and requirements:

●Suction-Feed Sandblasters:

The suction sand blast machine is powered by compressed air, through the high-speed movement of the airflow in the gun to form a negative pressure, the abrasive is through the sand pipe into the gun and shot from the nozzle, sprayed to the surface being processed, to achieve the desired processing purpose.

Advantages:

a. long time continuous sandblasting operation;

b. Lower cost of equipment;

c. 36-600 mesh non-metal abrasives, metal abrasives below 0.4mm can be used;

d.Low air consumption;

Weaknesses:

a. The efficiency of sandblasting is relatively low, not suitable for spraying metal abrasives larger than 0.4mm;

b.Smaller blasting distance, the best blasting distance is 50-150mm;

●Pressure Sandblasters:

The pressure sand blast machine is powered by compressed air, which builds up the working pressure in the pressure tank (also known as the sand tank). The abrasive enters the sandblast hose through the pressure of the regulated sand valve and is ejected from the nozzle at high speed to the processed surfaces to achieve the desired processing purpose.

Advantages:

a.High efficiency of sandblasting;

b.Sandblasting abrasives use a wide range, 8-120, of various abrasives that can be used;

Weaknesses:

a. It is not easy to realize a long time continuous sand-blasting operation;

b.It is necessary to use a double-bin continuous pressurized sand blasting machine;

c.Not suitable for spraying abrasives finer than 120 mesh, easy to appear a pulse phenomenon;

d.Higher equipment costs;

In dry blasting, compressed air is both the power of material supply and the accelerating power of the jet. In press-in dry blasting, the time and stroke of the abrasive accelerated by compressed air are much larger than those of suction dry blasting (only in the spray gun).

●Wet Sand Blasting:

The difference between wet blasting and dry blasting is that dry blasting is not suitable for cleaning grease and dirt, while wet blasting does not have this problem.

Wet blasting is more suitable for golf ball-type workpiece surfaces that need to avoid the color difference on the surface of the material caused by the heating up of the sandblasting.

The most important feature is the use of micro-powder abrasive, wet blasting has a unique use of the effect, while the dry type has its limitations.

Generally, if the abrasive size exceeds 400#, you must consider using a wet sand blasting machine.

When the abrasive is too fine, the dry pressure blasting sand has the appearance of sand pulsation, and the production of sand and dust separation has a certain degree of difficulty, we can use the cyclone to separate to the finest grit is 600 mesh green silicon carbide, finer grit needs to be verified!

When using pressure blasting, finer than 120 mesh abrasive will have a pulsation phenomenon, using pressurized sandblasting is not recommended finer than 120# of abrasive.

Advantages:

a. Ultra-fine abrasive can be used for surface treatment of precision workpieces(600-1200 mesh abrasive as far as possible with liquid sandblasting);

b. Clean up oil-contaminated workpieces, etc., in the case of non-filtering first de-oiled, can only use a liquid sandblasting, maintenance of automotive parts containing oil can be prioritized when choosing a liquid sand blasting machine, sand blasting liquid recycling, sand consumption is low, the nozzle wear and tear is small;

c. Good sealing, no dust pollution;

d. Simple operation, low failure rate, closed chamber, low noise;

e. The sprayed products have little damage and can be sprayed to very fine;

f. Stainless steel or fiberglass body, durable;

Weaknesses:

a. Low efficiency of sandblasting: To prevent carbon steel parts from rusting, they need to be added to the sandblasting liquid to prevent the rusting of iron workpieces;

b. Need to deal with sewage, easy to freeze in winter in the north, need to add antifreeze, the overall processing cost is higher;

Therefore, dry blasting can be used as much as possible with dry blasting.

Advantages of using Taisheng Machinery sand blasting machine:

Efficiency and Speed: Taisheng Machinery offers a wide range of types of sandblasting equipment such as drum type, suspended type, and roller pass type. These machines are designed to efficiently handle workpieces of different shapes and sizes, increasing the speed and efficiency of the blasting operation.

Cost-effectiveness: The company has specialized in the production of sandblasting equipment since 2007, with rich experience and professional design capabilities. By providing standardized and customized products, Tyson Machinery is able to meet the specific needs of customers, avoiding unnecessary expenditures and improving cost-effectiveness.

Abrasive Versatility: Taisheng Machinery’s sandblasting equipment is suitable for a wide range of abrasives, including stainless steel shot, wire cut shot, steel shot steel grit, aluminum oxide, ceramic beads, glass beads, and walnut shells. This versatility allows users to choose the right abrasive for different surface treatment requirements.

Environmentally friendly options: The company provides a sandblasting room and sandblasting equipment equipped with a dust collector, which helps to reduce dust emissions, improve the working environment, and meet the requirements of environmental protection.

Mechanical quality and after-sales service: Taisheng Machinery has strong manufacturing capabilities and a professional design team to provide high-quality sandblasting equipment. In addition, the company provides complete surface treatment solutions to ensure that customers receive comprehensive technical support and after-sales service during the process.

Conclusion

Understanding the function and application of sandblasting machines is the key to realizing the best surface treatment effect. By choosing the right equipment and abrasive media, industries can effectively solve a series of problems such as low efficiency, high labor costs, unstable surface treatment quality, dust pollution and environmental protection pressure, and difficulties in handling complex workpieces in traditional processes. This is the core reason for the popularity of sand-blasting machines.

TaiSheng Machinery has always been committed to providing innovative, reliable, and demand-driven sandblasting solutions to help various industries meet ever-changing challenges. Our team of professionals will customize the optimal solution for your specific needs, ensuring that every process achieves a superior surface finish.

Contact us today to learn how our expertise and state-of-the-art equipment can revolutionize your production process and help you achieve your goals of higher efficiency, lower cost, and better quality surface preparation!

]]>In today’s fast-paced industries, off-the-shelf solutions often don’t meet the specific needs of certain projects. Custom sandblasting and shot blasting machines offer a range of benefits over standard options:

1. Optimized for Your Production

Each business has unique production requirements. Custom-built machines ensure that your specific needs—whether they are production speed, size of components, or surface finish—are met. With custom equipment, you can reduce inefficiencies and optimize your process from start to finish.

2. Precision for Complex Projects

Some industries require high levels of precision, especially when dealing with delicate materials or components with intricate designs. Custom machines allow you to fine-tune the process for maximum precision, whether you are cleaning, polishing, or preparing surfaces for further treatment.

3. Cost Efficiency in the Long Run

While custom machines may come with a higher initial investment, they often lead to greater cost savings in the long term. With a machine built specifically for your operation, you’ll see reduced downtime, improved workflow efficiency, and less waste, which ultimately lowers operational costs.

4. Adaptable to Unique Materials

Different materials, such as metal, glass, ceramics, or even plastics, require specific abrasive media and techniques. Custom machines allow you to select the best options for treating your materials without compromising on quality or risking damage.

—

Our Customization Process

At TS Machinery, we follow a streamlined process to ensure that every machine we deliver is built to the highest standards and meets your exact specifications. Our team of experienced engineers, technicians, and support staff work closely with you every step of the way.

1. Understanding Your Needs

The first step in our process is an in-depth consultation to understand your business needs. We take the time to learn about your production goals, the materials you work with, and any unique challenges you face. Key questions we explore include:

– What type of material will you be treating?

– What are the sizes and volumes of the parts being processed?

– What is the desired surface finish?

– Are there any space constraints or specific operational requirements in your facility?

– What type of dust collection or environmental controls are needed?

This thorough needs assessment allows us to create a machine tailored to your specific production environment.

2. Designing the Right Solution

Once we have a clear understanding of your needs, our design and engineering team works on creating a custom solution that fits your operation. We use the latest CAD software and 3D modeling tools to design machines that maximize efficiency, precision, and durability.

During this phase, you’ll have the opportunity to review the design and provide input. Whether you require automated systems, specialized nozzles, or advanced dust control systems, we ensure that every feature is built to your specifications.

3. Precision Manufacturing**

At TS Machinery, we pride ourselves on the quality of our craftsmanship. Once the design is finalized, our team of skilled technicians begins the manufacturing process. We use advanced CNC machining, laser cutting, and high-precision assembly to ensure that every component is built to the highest standard. The result is a durable, reliable machine that will stand the test of time.

Before delivery, we conduct rigorous quality checks and performance tests to ensure the machine meets all operational requirements and exceeds your expectations.

4. Installation and Training

Once your custom sandblasting or shot blasting machine is ready, we provide full installation support to ensure seamless integration into your production line. Our team will set up the machine, run test operations, and provide detailed training to your staff on how to use the machine effectively and safely. This helps minimize downtime and ensures smooth operation from day one.

5. Ongoing Support

At TS Machinery, we believe in building long-term relationships with our clients. That’s why we offer continuous technical support after installation. Whether you need troubleshooting assistance, spare parts, or routine maintenance, our team is always here to help you keep your operations running smoothly.

—

Applications of Custom Sandblasting and Shot Blasting Machines

Our custom machines are versatile and can be designed for a wide range of industries, including:

– Automotive: Surface cleaning, rust removal, and polishing of automotive parts such as engine components, frames, and body panels.

– Aerospace: Precision cleaning and surface preparation of aircraft components, including landing gear, fuselage parts, and turbine blades.

– Construction: Removing rust, paint, and other contaminants from large steel beams, concrete structures, and construction materials.

– Manufacturing: Cleaning and deburring metal parts, tools, and molds to prepare them for painting, coating, or other finishing processes.

– Marine: Removing scale, corrosion, and marine growth from ship hulls and other maritime components.

No matter your industry, we can provide custom solutions that fit your specific requirements.

—

Why Partner with TS Machinery?

At TS Machinery, we’re more than just a machinery provider—we’re a partner dedicated to helping you succeed. Here’s why businesses across industries trust us with their surface treatment needs:

– Experience: With years of industry experience, we have a deep understanding of the challenges you face and how to overcome them with the right equipment.

– Quality: Our machines are built with top-grade materials and undergo rigorous quality testing to ensure long-lasting performance.

– Customization: We don’t believe in one-size-fits-all. Every machine is custom-built to meet your specific needs, ensuring optimal performance in your production environment.

– Customer Support: From initial consultation to installation and beyond, we provide expert support to help you get the most out of your investment.

—

Contact Us for Your Custom Solution

Are you ready to enhance your production process with a custom sandblasting or shot blasting machine? Contact TS Machinery today to discuss your unique requirements. Our team of experts is ready to help you find the perfect solution for your business.

[Get in Touch Now]

]]>Off-the-shelf machines are great for general use, but many industries require specific equipment that can meet the demands of their unique processes. Custom-built sandblasting and shot blasting machines offer several distinct advantages:

####1. **Tailored to Your Specifications**

Every business has its unique operational challenges, and standard machines may not address them effectively. Custom-built machines are designed around your specific production requirements, such as material type, production speed, and surface finish. This means fewer bottlenecks, more streamlined operations, and improved overall efficiency.

#### 2. **Greater Precision for Complex Applications**