The initial concern for anyone selecting a reliable shot blasting machine involves determining its price point. The price of a shot blasting machine does not follow a universal pricing model since it depends on multiple factors. The equipment price depends on your requirements, as well as your production needs and the specific features your operations demand.

What Is a Shot Blasting Machine?

The shot blasting machine functions through blasting metal surfaces with high-speed steel shots or abrasive materials to achieve cleaning and strengthening, or polishing operations. The manufacturing process heavily depends on this equipment because surface quality represents a critical factor.

A reliable blast cleaning system provides consistent results, together with reduced manual labor and improved surface adhesion when treating steel pipes, cleaning weld seams, and preparing parts for coating.

What Affects the Price of a Shot Blasting Machine?

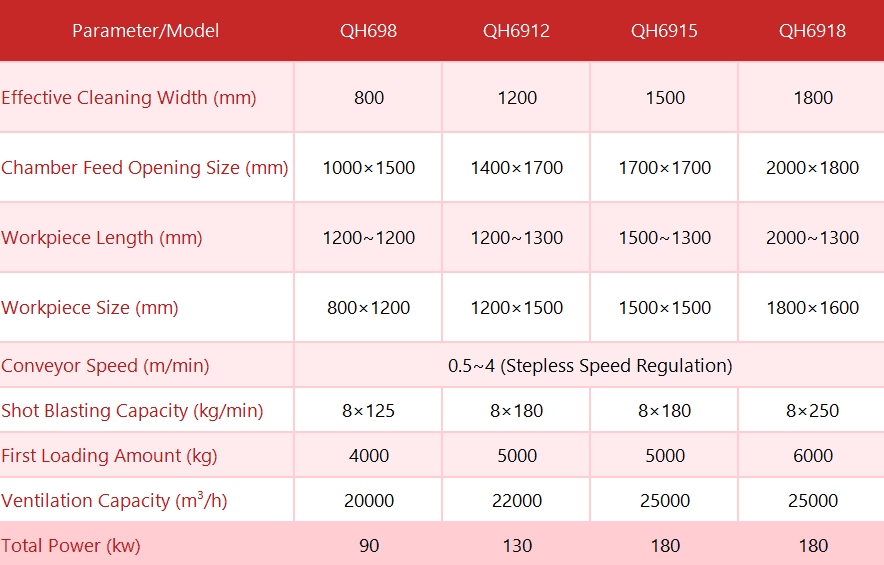

1. A roller conveyor shot blasting machine designed for cleaning large steel plates operates at different price points than portable shot blasting machines intended for maintenance work.

2. The cost of fully automatic shot blasting machines increases with the addition of PLC control and touch screens, as well as blast wheel regulation systems, which also reduce future labor expenses.

3. The price of equipment increases with machine size and throughput capacity, but these larger machines enhance production rates.

4. The price of dust collection and recovery systems increases with advanced models that protect workers and recover abrasive materials. Although the initial cost may be higher, the system will pay itself back in the long term.

Do you require a chamber of unique dimensions or a custom-designed media recovery system? The price of customized machines reflects their value, yet they remain an essential investment. Their cost will be determined by the level of investment made.

Different Types of Shot Blasting Machines and Their Value

The selection of appropriate shot blasting equipment heavily depends on your production needs. The following list presents various machine types along with their most valuable applications.

🔹 Through-type Shot Blasting Machine

Features and scope of application:

This series belongs to the roller table type shot blasting cleaning machine, mainly used in industries such as construction and bridges, for stress relief and surface rust removal of large-sized steel structural components such as l-beams and H-beams.

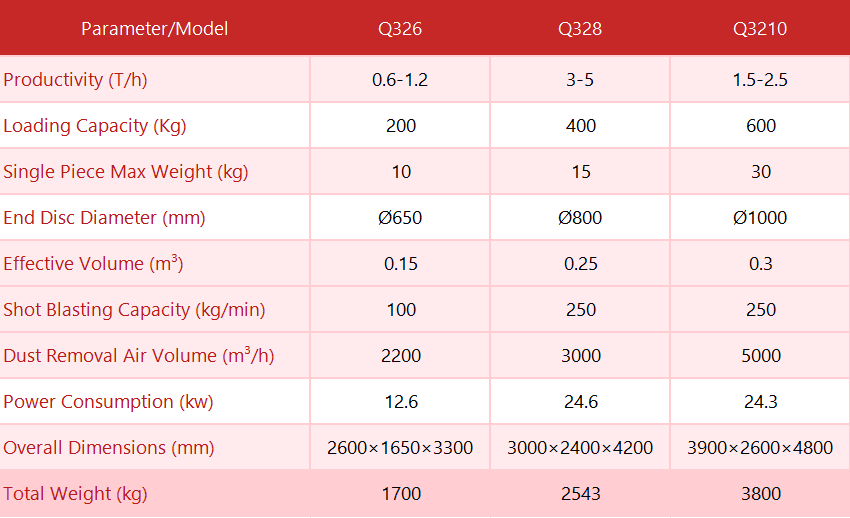

🔹Tumble Belt Type Shot Blasting Machine

Characteristic:

1. Surface cleaning, rust removal, and shot blasting strengthening processes for various small and medium-sized castings, forgings, and machined parts.

2. It can be used alone or in combination with multiple machines, forming a production cleaning assembly line with continuous conveyors and other supporting equipment.

3. Advanced design, reasonable structure, low energy consumption, and high efficiency.

Scope of application:

Small and medium-sized mold castings, forgings, stamping parts, non-ferrous metal castings, gears, and springs.

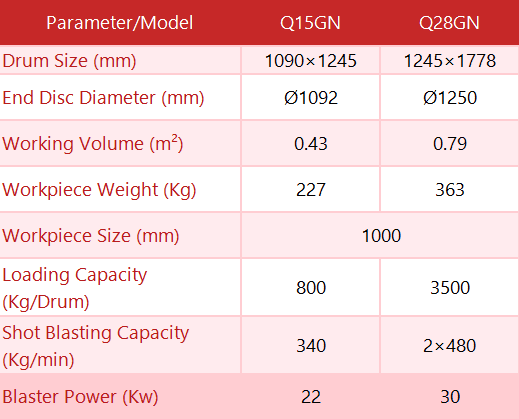

🔹Automatic Loading and Unloading Track-Type Shot Blasting Cleaning Machine

Characteristic:

1. Adopting an automatic loading and unloading system to achieve an automated workflow, reduce manual labor, and improve efficiency.

2. The tracked conveyor system has high stability and smooth operation.

3. Using a high-speed rotating shotblaster to spray steel balls onto the surface of the workpiece can effectively remove surface contaminants such as oxide skin and rust, resulting in a thorough cleaning of the workpiece surface.

Scope of application:

Castings, forgings, welded parts, nonbrittle parts that are prone to rolling, falling, and not easily crushed, as well as castings, aluminum castings, or certain non-ferrous metal workpieces with shallow cavities.

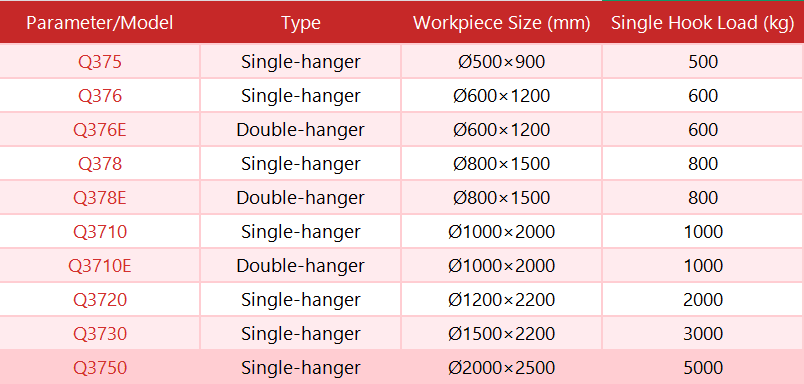

🔹Hanger blasting machine

Features and scope of application:

This series is a hook shot blasting cleaning machine, mainly used for surface cleaning of castings, structural components, non-ferrous alloy parts, and other parts. This series of shot blasting cleaning machines is divided into single hook, double hook, lifting, nonlifting, and other models. It has the advantages of no pit, compact structure, and high productivity.

Why Prices Can Vary Between Manufacturers

Multiple manufacturers of shot blasting machines present substantial differences in their market prices. But why?

- Equipment constructed with thicker steel components and premium materials costs more at first, but delivers extended operational periods.

- A machine with no after-sales support becomes more expensive in the long run than a machine with a low price and technical support.

- Safety & Compliance: Certified machines that meet CE or ISO standards may have a slightly higher price, but offer peace of mind.

- Machines produced in areas with high labor expenses become more costly to purchase.

At Taisheng Machinery, we believe in delivering value, not just a price tag. Our machines are designed for durability, built with quality materials, and backed by a global service team.

What to Consider Before Buying a Shot Blasting Machine

Purchasing a shot blasting machine requires considerations beyond its technical specifications and price point. Ask yourself:

- What material and surface finish do I need?

- The machine usage rate will determine its frequency of operation.

- Dust control stands as a fundamental requirement in my workplace operations.

- A manual or automated system choice falls under my requirements.

- The maintenance operations and spare part management procedures I need to establish are what I need to consider.

Every process receives guidance from our team.

We will assist you through the entire process, starting with blasting media selection, followed by installation support.

We have everything you need.

Top Features of Taisheng Shot Blasting Machines

Why do clients across 30+ countries choose Taisheng?

🔹 Compliance with Global Environmental Standards

The equipment includes high-efficiency dust collectors that fulfill CE, OSHA, and local environmental standards. The system provides clean air emissions and protects worker health, which makes it suitable for Europe and North America, and countries with strict environmental laws.

🔹 Automated Operation to Reduce Labor Costs

The equipment includes PLC automation together with smart controls and preset programs. The machine operates best in Japan, and UK, and Australia because these countries value both precision and labor-saving features.

🔹 Heavy-Duty Build for Harsh Environments

The equipment features wear-resistant steel construction along with robust components that operate in extreme heat, humidity, and dust environments. The equipment operates best in the Middle East, Africa, and Southeast Asia regions.

🔹 Flexible Machine Configurations

The product range includes roller conveyors, hook type, tumble belt, and custom models. The equipment serves complex and large workpieces and varied workpieces in the construction, steel casting, and fabrication industries.

🔹 Energy-Saving and Abrasive Recycling Design

The blast wheels operate at optimal levels, and VFD control and media reclaim systems decrease energy consumption and abrasive usage, which benefits companies by lowering operational costs and carbon emissions in eco-conscious markets.

Let’s Find the Right Machine for Your Business

The acquisition of a shot blasting machine requires substantial consideration because it represents a major purchase decision. A purchasing shot blasting machine requires more than cost information because you require specialized guidance and dependable technical backing, as well as equipment suited to your production workflow.

Please share details about your project so we can offer a customized solution that suits your specific needs.