I hope you enjoy reading this blog post. If you are looking for sandblasting machine solutions, feel free to contact us.

Still scrubbing away rust, grease, or flaky paint with wire brushes and toxic chemicals? Spending endless hours trying to restore metal parts—only to end up with uneven finishes and a dusty mess?

There’s a better way.

Say hello to vapor blasting—a powerful, eco-friendly, and precise method of surface preparation that’s quickly becoming the go-to choice in industries from automotive restoration to aerospace engineering.

In this guide, we’ll cover everything you need to know about vapor blasting, how it works, where it’s used, and why it may be the smartest surface finishing solution for your business. If you’re searching for vapor blasting near me, you’re in the right place.

What Is Vapor Blasting?

The advanced cleaning method of vapor blasting (also known as vapour blasting or wet blasting) uses abrasive media combined with water and compressed air to refine and clean surfaces. Vapor blasting machines operate without generating substantial dust or friction, enabling their use on delicate components and precise work applications.

The process operates as dustless vapor blasting since it minimizes airborne particles, protecting workers and environmental conditions.

How Does Vapor Blasting Work?

Any vapor blasting machine relies on a sophisticated technology combination:

● The vapor blasting water pump unites water with abrasive media.

● The compressed air system drives the slurry through a nozzle.

● A gentle procedure uses the mixture to eliminate contaminants and oxidation, paint, and coatings without harming the base material.

Water acts as a protective barrier between abrasive forces, so the final finish becomes more even than traditional dry blasting methods.

The results achieved through vapor blasts before and after treatment produce truly exceptional outcomes. Your components can achieve a brand-new appearance without sustaining any surface damage.

Applications of Vapor Blasting

Ready to tackle surface contaminants like a pro? Vapor blasting is a game-changer. With its ability to combine water and abrasives while adjusting pressure levels, it offers a powerful yet gentle cleaning solution for countless industries. Whether you’re restoring a classic car or prepping industrial equipment, here’s how vapor blasting shines in real-world scenarios.

Automotive Restoration

Bringing old vehicles back to life? The process allows complete removal of paint along with rust, primer, and filler through one single operation. The water component in this process prevents surface warping which traditional sandblasting often causes. The process produces smooth surfaces that are ready for primer application without damaging sensitive metals.

The best part? You can do it all with a compact vapor blaster cabinet—ideal for restoration shops and mobile setups.

Marine Maintenance

Vapor blasting provides high-quality maintenance services to fiberglass hulls and aluminum boat components. The system decreases airborne dust and simplifies cleaning operations, especially in waterfront areas. It excels at uncovering concealed blister damage and restoring older ships with fresh surfaces.

Concrete Resurfacing

Need to remove stains, sealers, or multiple layers of paint from concrete? The best approach is dustless vapor blasting. Dry blasting poses safety risks since concrete contains silica. The combination of dust reduction and cleaning performance makes this method ideal for construction environments.

Pool Restoration

This method gives your pool multiple renewal options. Remove thick paint or plaster layers, or gently clean tiles using adjustable pressures and softer abrasives—without damage or mess. For contractors, this means faster turnarounds and safer working conditions using vapor blasting equipment.

Powder Coat Removal

Forget heat guns and scraping sticky residue. Vapor blasting cools the surface, turning coatings brittle and easy to remove. Whether you’re dealing with automotive parts or aluminum panels, it’s the cleanest way to prep for repainting.

Other Handy Applications

Vapor blasting isn’t just for big jobs. It’s also a go-to for:

● Graffiti removal

● Epoxy and coating removal

● Cleaning wood, brick, stone, boats, machinery, antiques, and more

● Eliminating grime, grease, mold, calcium, corrosion, and other tough residues

Why Choose Vapor Blasting?

Because it’s effective, environmentally safe, and surface-friendly. The precision and power of vapor blasting make it the top choice for contractors, restoration specialists, and maintenance professionals who require results without the mess.

Whether you use a vapor blaster cabinet or a full-scale system, Taisheng’s vapor blasting equipment delivers the performance you can rely on.

Benefits of Vapor Blasting

● Dustless Operation: Say goodbye to messy, hazardous environments.

● Eco-Friendly: Uses water instead of harsh chemicals.

● Surface Preservation: No warping or distortion, even on thin or soft metals.

● Better Visibility: Water keeps abrasive particles contained, improving blasting visibility.

● Improved Finish: Produces a clean, matte surface ideal for painting or coating.

For manufacturers and repair shops, this translates to:

● Higher efficiency

● Reduced rework

● Lower operational costs

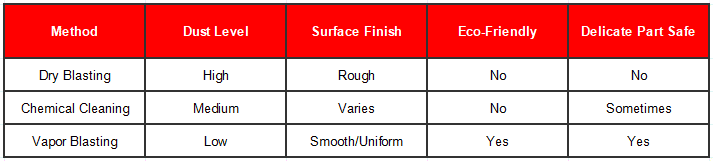

Vapor Blasting vs. Other Methods

Let’s quickly compare vapor blasting with traditional alternatives:

Vapor blasting stands out for its ability to clean with care.

Which Vapor Blasting Machine Is Right for You?

If you work in:

● Automotive

● Aerospace

● Electronics

● Metalworking

● Medical equipment

Then vapor blasting may be exactly what you need. It’s especially valuable for high-value, delicate parts and when uniform surface finishes are required.

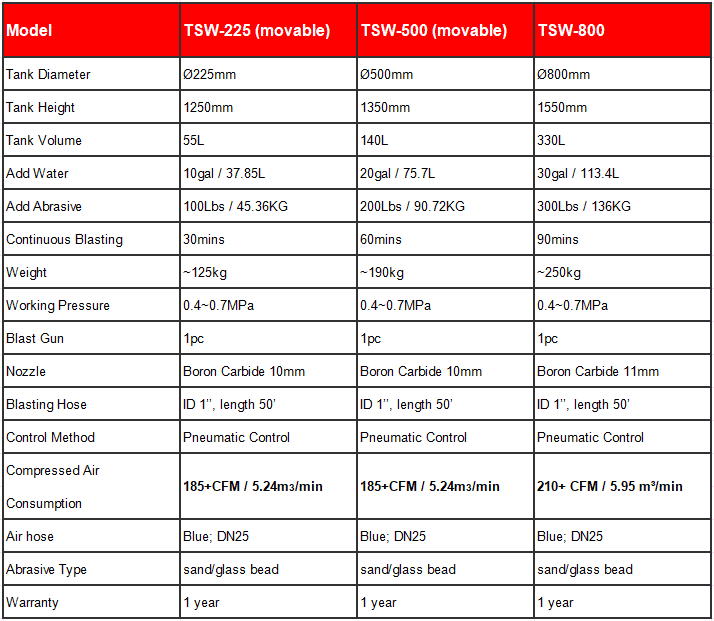

Using a system that’s too large or small wastes time, energy, and compressed air. That’s why Taisheng offers a full range of vapor blasting machines, including mobile models and vapor blaster cabinets.

Taisheng Vapor Blasting Models at a Glance

Below is a side-by-side comparison of our TSW-225, TSW-500, and TSW-800 mobile vapor blasting units. Find the perfect match for your job.

Real-World Results: Vapor Blast Before and After

Seeing is believing. Our client’s report:

● Up to 60% faster cleaning times

● Longer equipment life through non-destructive cleaning

● Lower fatigue, better health compliance

Before: Corroded, unusable parts

After: Clean, functional, finish-ready

That’s the vapor blast before and after difference.

Ready to Upgrade Your Surface Cleaning?

Still, using outdated or damaging methods?

Vapor blasting gives you a smarter, safer, and more effective solution. Whether you’re searching for vapor blasting near me or looking to build your setup, Taisheng’s vapor blasting equipment is engineered to meet your toughest surface prep demands.

Let’s talk! Send us a message today—we’ll help you upgrade your workflow and results.

Vapor blasting is just one of many methods in the world of surface treatment. If you’re curious about other techniques, equipment specs, or process planning, here are some expert resources from our team: